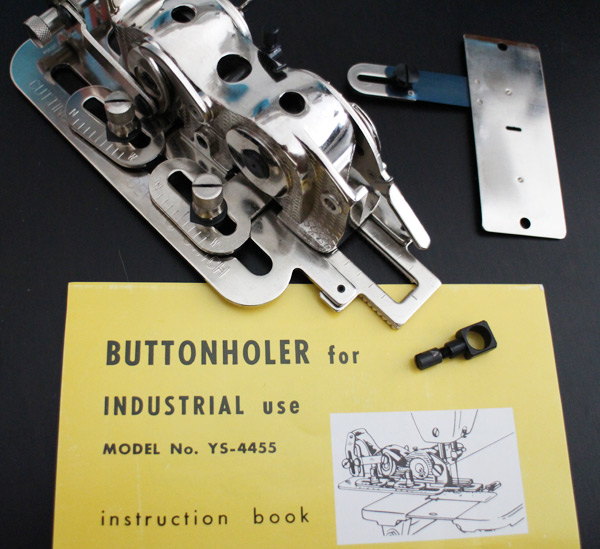

Industrial Buttonhole Attachment

There is lots of information about buttonhole attachments for old household Singers, but after a little research, I didn’t find many people talking about buttonhole options for industrial machines. Sure, there are industrial machines you can buy that do nothing but sew buttonholes, and while I would love to own one of those machines, they are expensive and take up a lot of space.

These attachments have been around for a while and seem to fit just about any single needle, straight stitch, industrial sewing machine.

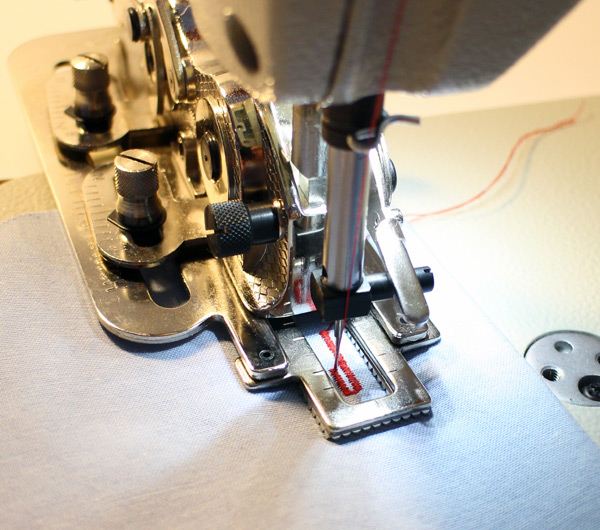

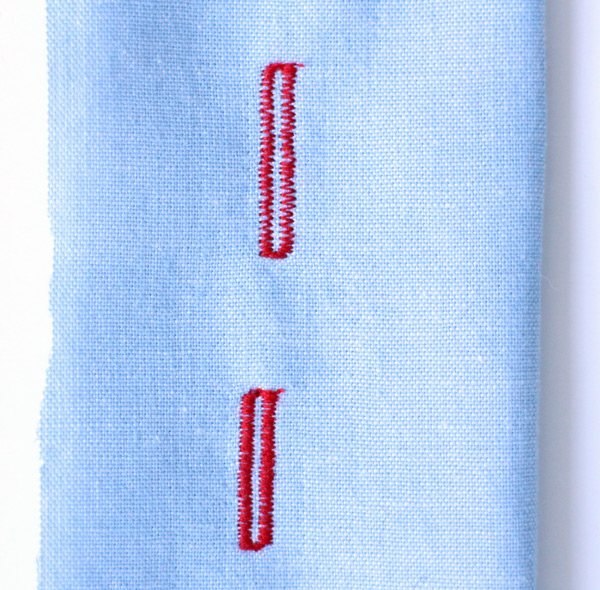

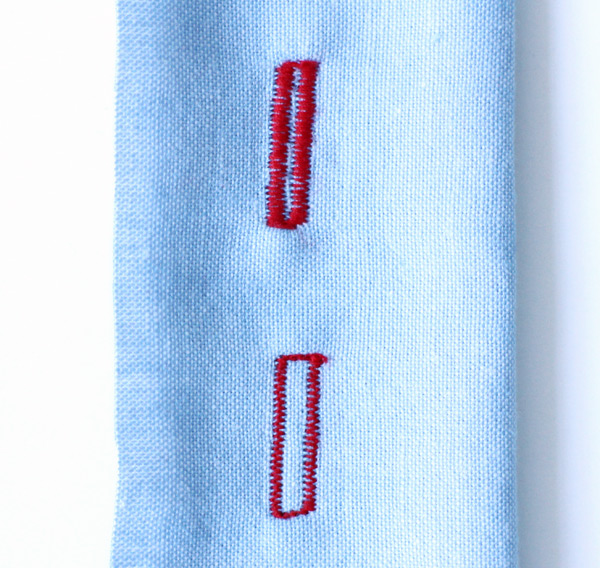

You can adjust the number of stitches (space between stitches) that make up the buttonhole, as well as the length of the buttonhole. The stitching generally turns out more consistent than what is shown below. I may need to adjust the tension on my machine.

The width of the actual stitches can also be adjusted, as well as the cutting space down the center of the buttonhole.

I’ve been using this in any place I need a buttonhole as I don’t like the buttonholes that my household PFAFF makes, but it isn’t perfect. The main issue is that the attachment doesn’t really do a proper “tack” at the top and bottom of the buttonhole. It does a little “side stitch thingy” before stitching each long side of the hole, and I’m not quite sure how this will hold up overtime.

I also wish that the attachment could create a keyhole style buttonhole, but it can only do the standard style hole. My last criticism is that while the attachment can be adjusted to create short and long buttonholes, the longest it can go is around 1″ or 7/8″. For large waistband buttons, I wish it could go just a little bit longer.

Overall though, it gets the job done, and is fairly reliable. I’ve used it on a couple of shirts, and the last two or three pairs of pants I’ve made and all of the buttonholes are still in good condition. For anyone with a basic straight stitch industrial sewing machine, this might be an attachment you want to look into, just to have another option for those pesky buttonholes.

I’ve been looking for something like this (not very astutely I guess). Do you need to have a way to drop your feed-dogs or to cover them? It seems to me that a combination of the little side-step stitch AND a bar-tack would give a perfect button-hole strength right where you need it most. I should look into whether my old Rex straight stitch could fit one of these. Thanks!

The attachment comes with a cover for your feed dogs (shown in the upper right corner of the first image above). This cover screws into your machine bed. Unfortunately the set screw for the feed dog cover, which is very specialized and not easy to replace, broke. I am able to lower the feed dogs on my machine though so I can still use the attachment.

I have been going back and placing small bar-tacks on the top and bottom of the button holes, but this is somewhat time consuming.

Wonderful review. Shame about the non back tacking. Probably not ever going to be a problem, just an annoyance. Shame you’re not in California, we could go 50/50 on a Reece 101.

Man, I would love to share a Reece! That would be the way to do it though, split the cost and share the machine.

Wondering if you have any idea if this would work on a Juki 2010q?

Facing similar challenge myself, it seems that the most cost effective way (I too would love to be able to afford a Reece!) would be to use a 1950’s “Greist” type buttonhole attachment with Cams. These can do a keyhole buttonhole…the challenge comes finding the correct size keyhole cam.

Hi Giedra,

I’m not sure if this attachment will work on your particular machine. You might want to find a retailer with a good return policy to try it out, in case it doesn’t work. Can you lower the feed dogs on your machine?

Taylor

Johnny,

I’ve thought about trying one of those cam attachments. Do you know if those “Greist”type attachments will fit on a modern industrial machine? I’m not sure if my presser foot bar is the same size as the the presser foot bar on the older machines those were designed for.

Taylor,

As far as I know they were designed for domestic machines, if you get an old singer or domestic “low shank” machine it should fit. I’m hoping to use one on an old Bernina (with an adaptor).

I agree it’d be better to get one for industrials but i know of no such thing 🙁

My buttonhole procedure is to keep a Singer buttonholer set up on one of my Pfaff 130’s. The Singer can do a buttonhole as long as 1 1/16″. I also have another buttonholer by Singer for their slant needle models that can do up to 1 1/2″ buttonholes. My sewing contractor friends tell me that these buttonholes are better than the ones they make on their industrial buttonholers. For those who don’t know, an industrial buttonholer will position, sew, and slash the buttonhole in seconds, but take a look at a RTW shirt and notice just how poorly they look. You get speed at the cost of quality.

Hey Taylor,

What thread size (tex #) are you using for your shirt buttonholes? I’ve always had issues trying to get a good buttonhole b/c of tension problems and think it might have something to do with the thread size I’m using. I’ve had buttonholes done in NY to combat this.

Also, assuming you have the tension set properly for straight stitch when constructing a shirt, is there a consistent amount you turn clockwise/counter-clockwise when you slap the attachment on?

I’m not using an industrial sized thread for shirt buttonholes. I use an “all-purpose” weight home sewing machine thread. There is probably something better to use, but I stick with all-purpose for shirts.

I usually don’t have to adjust the tension that much when using this attachment. Sometimes I’ll put a different color of thread in my bobbin just to check the tension balance, and make adjustments from there. But generally, nothing major when using the attachment.

I have never seen seen such immaculate sewing, those jeans are just plain gorgeous! Your blog is terrific too I might add. I was wanting to pick your brains about that industrial button hole foot: where might I find one of those and I presume it will fit a Brother straight stitch industrial……many thanks for any info and I look forward to more pics of perfect shirts! Deborah

Hi Deborah,

Do a Google search for “industrial buttonholer” and you will see lots of options.

That is meant to be the Japanese Yoshikoshi YS-star. See model details and buttonhole samples:

http://www.yoshikoshi.mfg.co.jp/CONFERENCE%20ROOM.html

This will do a proper bar tack by removing some screw. I found a copy of the instructions somewhere.

There are cheaper clones about now, of unclear quality.

The vintage Singer/Greist one will do more fancy shaped buttonholes.

This is the most complete description I have found of the Greist buttonholer. http://edsmum.wordpress.com/2010/11/07/griestgreist-template-buttonholer-attachment/

I believe the right model (probably #10 or #10Z) does work with industrial type high-shank machines. I think I read in a sewing forum people are using them on the semi-industrial quilting machines than fit industrial feet. The Greist model descriptions are all on the back of the box – photos can be seen on ebay listings.

(BTW Taylor, having read more of your blog, I can’t believe how good your sewing is after such a short time!)

Taylor’s YS-4455 looks like the genuine article. Please note there are cheap clones being advertised as the real thing. This page shows the brand marking from the manufacturer. http://www.yoshikoshi.mfg.co.jp/ATTENTIONhtml.html

The photo of the star logo on the left side crank arm is missing. There is also a star logo on the underside of the feed dog cover plate.

I have seen many accessories in the sewing market advertised using manufacturer part numbers for non-genuine items. Buyers take care.

I saw this thread from over 5 years ago last week as I researched for an attachment for my industrial juki. I ended up buying an old Greist buttonhole attachment from Ebay. I knew it wouldn’t fit my juki industrial so I removed the feed dogs from my old Brother domestic machine and attached the Greist. With a denim needle installed it easily goes through a couple of layers of denim to create great keyhole button holes. I go round the button hole twice to get a thicker, sturdier button hole. For only £15 online put on an old machine laying around, its worth it!

I am looking for a buttonhole foot (high shank)for a Harrison straight stitch machine. Can someone please advise where I can purchase one. (DESPERATE)

Hi, I am looking for something like that to make the buttonholes but this publication is 2013, it is still possible to get this accesory? If yes, please let me know how can I buy it. If you can mail me the answer, I will appreciate it.

Hi, I think it is still possible to buy this accessory. Search for “industrial buttonhole attachment Star YS-4455” and you should be able to find it.

Do you know of any attachments for keyhole button holes? I would really like to be able to do them, but my machine only has a standard one step buttonhole.

Unfortunately I don’t. I wish there was one available as I too would like to make keyhole style button holes on my industrial machine.